By Joe Barry, South Africa

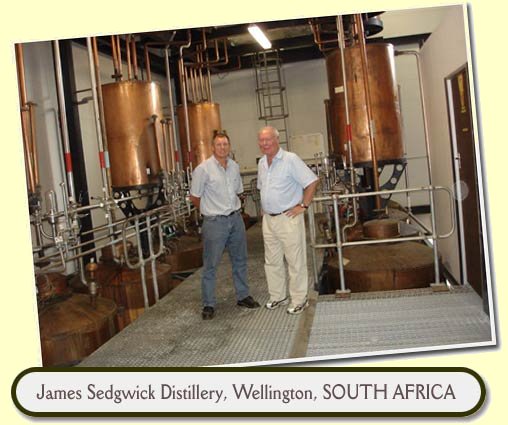

Interview with Andy Watts, manager of a whisky distillery in Wellington, Cape, South Africa that produces the ‘Three Ships’ whiskies; James Sedgwick Distillery. Conducted on 8 February 2007 by Joe Barry

Interview with Andy Watts, manager of a whisky distillery in Wellington, Cape, South Africa that produces the ‘Three Ships’ whiskies; James Sedgwick Distillery. Conducted on 8 February 2007 by Joe Barry

Andy thanks for agreeing to this interview. Perhaps the first thing you could talk about is your involvement with whisky. What’s been your history so far?

Well my history with whisky and with Three Ships in particular goes back to 1984 when I first started working with the company Stellenbosch Farmers Winery (now Distell). In 1987 I got the opportunity to go back to Scotland where I worked for 7 months with a company called Morrison Bowmore Distillers who have 3 distilleries, Bowmore on the island of Islay, Glen Garioch in the

Highlands and Auchentoshan the only Scottish tripled distilled whisky in the Lowlands. I then moved to Wellington to the distillery here where from 1989 onwards they established it as the home of South African whisky. Our operations before that used to be in Stellenbosch at a small distillery called R&B and when the lease expired we moved the whole operation across to Welllington and since 1989 I have managed this site and headed up the production of Three Ships.

The website states that the Three Ships brand was actually launched as far back as 1977. What happened before you got here?

That’s right. In 1977 Three Ships was launched under the marketing skills of Mr Francis Norton an extremely mad Irishman with a passion for whisky but in 1977 when it was launched it wasn’t actually a fully fledged whisky because it contained matured Scottish malt whisky and unmatured South African grain whisky. It was only in 1981 that Three Ships became a fully fledged whisky meaning that both the grain and malt components had now matured for the minimum legislated period of 3 years.

That was my next question, is the South African minimum 3 years like Scotland?

Yes. The legislation in S.A. is basically word for word the same as what it is in Scotland – in terms of maturation period and in terms of raw materials used, additives for example can only come from the grain, there can be no flavours added, there can be no sugars added, so yes almost word for word our legislation here in SA is the same as Scotland.

The Bourbon Cask finish has a no age statement but was apparently six months in first fill Bourbon casks.

How long was it in other casks and what casks were they?

Any whisky which has a no age statement on the label you can take for granted has been matured for a minimum of 3 years so the base of the bourbon cask finish has been matured for the minimum of 3 years. What we did then was we selected the right blend of malts and grains and put them back for a further six months into first fill American oak casks. The whiskies we chose at that stage made up the first fully South African whisky in other words the malt and the grain were both distilled and matured in SA so the malts we chose were specifically very light in flavour so as not to fight against the extraction we wanted from the wood. In the original 3 year maturation period like in Scotland we use a lot of American oak and a small amount of ex brandy casks would also be in the mix for the malt maturation too.

Your website also says, talking now about the Single Malt, it is 100% natural – so you don’t add caramel?

That’s correct. The single malt as you can see from the bottle here in front of you, the colour in that is totally natural.

Most whiskies for consistency of colour do have caramel added to them at the bottling stage but the 10 year old as you see it here is as it came out of the cask.

Do you believe caramel can change the taste?

To be honest I don’t think so. The concentration of caramel is incredible; you need minute amounts to make the colour changes which you see in the bottle. I honestly do not believe it can change the quality or the taste of the whisky.

And chill filtering?

I think that’s a personal one too. I see the trend overseas is to move away from that – they say it is not natural to chill filter – in other words they are prepared to see a slight haze in the product and then to make the statement that this is now a purely natural product that you see and no chill filtering has taken place. Chill filtration does take out some of the flavours there is no doubt about that but I think in this country, in South Africa at the moment our customers out there are used to seeing a clean clear product and I think if you were in Bloemfontein in the winter and suddenly your whisky turned hazy you would probably get it back as a customer complaint. I don’t yet think our consumer is educated at a level to understand chill filtration and what the benefits and possible disadvantages of it are.

The website states it was made from imported malt, where did the barley come from?

The barley came from mainland UK. This is an interesting question – because a lot of people ask if you bring in the barley from overseas how can it be South African? The whole definition of Scotch whisky and South African as well, is where the product is distilled and matured. In other words at the moment in Scotland it is possible, as a result of shortages, for the grain component to be French wheat and the barley could come from Holland. To give you an example up until the mid 1980’s I would go as far as to say that 95% of all the grain used in Scottish grain whisky originated from the maize fields of South Africa. We exported vast amounts of maize to Scotland for the whisky industry. So yes we import our barley from overseas for the simple reason that there is no barley in South Africa which is suitable for distillation purposes. All the barley in this country available for liquid use is used up by South African Breweries.

And the same barley is then used for your standard blends as well?

Our original and the 5yo are still blends of SA and Scotch whiskies. I say SA first because that then means the majority of the whisky in these whiskies originates from SA, in other words is distilled and matured here in SA but there are still Scotch components in there too. The barley variety I use at the moment is Optic which is well established in the Scottish distilling industry but it is possible that other varieties are used in the base sourced in Scotland.

Your Single Malt which was a one-off won gold medals at the 2006 IWSC.

Do you have any plans to produce another single malt?

That’s a good one. Joe as we discussed I have many plans but how many of them are going to get to the surface I really don’t know. But yes I’ve products which have been identified for future releases and I think in view of the success of the 10 yo SM it would be very short sighted if we did not follow on that success with something on a more continuous basis. I think the 6000 bottles which were made whetted the appetite of a lot of people out there and it would be nice to give those people something on a continuous basis.

Andy, any sort of timeline you can give us?

Well I have product which is now ready but it is like an aeroplane at Heathrow airport, you have to wait for when you land and when you take off and our company has a lot of other products which are in that same line waiting to land and take off so you know they will stack me and rack me and fit me in when there is a gap.

Will it be a similar type formula or are you looking at something totally different?

The next project I am looking at is something totally different. The reason is that way back in 1977 when the idea was first pioneered to make a South African whisky you would have been absolutely stupid to have considered anything other than Scottish style whisky. The simple reason being that 99% of all whisky consumed in South Africa at that stage was Scotch and that was the trend right the way through the mid-90’s until we became a part of the global village. I think over the last few years in the new market which has emerged, consumers who are now moving to whisky are much more susceptible to change, in other words it is not necessary now to have a whisky which definitely follows the Scottish style, the time could now be right to say this is something which has a South African style, something which is really unique to South Africa. So yes even though 60% of the whisky consumed in this country is of a Scotch style the other 40% is growing at an amazing rate and I think there is no reason at all why we can’t stand on our own feet and do something slightly different and really South African.

Is there such a thing as a unique South African taste?

I think that is definitely in the hands of the marketers in how you actually market the product.

For example if you decided to go 100% South African maize, I don’t think there is anybody else in the world who is doing that so yes you would have something there which is definitely unique to this country. If you look at bourbons for example they must contain by law a minimum of 51% corn which is maize, if you look at Scotland at the moment there is only one grain distillery which still uses maize, the rest use wheat. So yes there would definitely be licence to say that we could make something unique.

Andy, some technical questions. How many waters is the wort made with, I understand 3 is the norm?

That’s somewhere again where we are very unique in our distillery and you will see that when we take the walk through. We do not do our mashing the traditional way they do in Scotland. Our equipment is slightly different, in other words we actually mash solids in, the same as they do in Scotland but we don’t separate in a mashtun we have other methods of separation before going to our pots and then with the grain whisky that is a continuous process so there is no separation.

What are the washbacks made of and how long is the wash in them?

Ours are all stainless steel and our fermentations are normally between 54 and 60 hours, we temperature controll our fermentations- we know the optimum temperature at which our yeast wants to operate therefore we hold at that optimum temperature putting very little strain on the yeast so it can do its job under the best conditions possible.

What yeast do you use?

We use a dried yeast which we put together specifically for our products, both our grain and malts, by Anchor Yeast a SA company. We find the dried yeast works very well for us and the chances of any infections to the dried yeast is much less than in the traditional pressed or cultured yeast they still use in Scotland.

At what strength are your casks filled?

Our malt off the pots comes normally around 68% ABV and that is filled at distilling strength, our grain we distill to 94.3% ABV and then we break that down with de-mineralised water to again around 65% to 68% ABV before maturation.

What are the floors in the cask storage area made from?

You will see when you look at our maturation stores things are slightly different here too, we have enormous warehouses which are concrete floored and we use the palletisation method for stacking which gives us maximum utilization of the space available.

On your standard brands the label says Scotch, presumably imported in bulk – which distilleries do you use?

That is correct. We work with two companies which are not part of the major stables, we’ve come a long way with Morrison’s as I have mentioned earlier and we also use Angus Dundee.

To make your blended product you need malt and grain whisky, do you have both systems on site?

Yes we do. Again I don’t think there are too many distilleries in the world which have got the capabilities of doing both grain and malt on the same site and what makes my job even more interesting is that where in a traditional or typical Scottish distillery you have a certain style of barley which you bring in and you produce that product day in and day out, I am in the position where if I want to bring in heavily peated malt and run that for two weeks I can and if I want to bring in unpeated malt I can do that as well. In other words I’ve got the whole spectrum which I can do here.

I can do from unpeated to heavily peated malts and I can do grain whiskies.

Do you have plans for any other products at the moment aside from the range we can see here?

We do do other products out of this distillery, other whisky products. 60% of the market in South Africa is still cut price spirits, be it brandy or be it whisky at this stage. So there is still a huge market out there for less premium products, not necessarily in terms of quality but maybe in terms of blend make up, and we do two products Harrier and Knights which also come out of this distillery as well.

Between 1886 and 1977 when whisky started here what did this distillery produce?

I think like every distillery in South Africa this distillery produced brandy and a small amount of gin but predominantly brandy.

Andy, a final question – this distillery is not open to the public.

Is there any particular reason why because surely if it was it would create more product awareness?

I could not agree with you more Joe – again I am racked and stacked until that idea gets off the ground. We sit with an absolutely stunning premises, we are 40 minutes away from Cape Town, there isn’t another commercial distillery in the country, everything is in our favour to do something like that. You are 100% right but I can’t tell you when because I honestly don’t know.

Well, we will have to bring some pressure to bear on your marketing guys!

I would really appreciate that support! (laughs).

Andy thank you very much indeed for the interview, it was really very interesting talking to you.